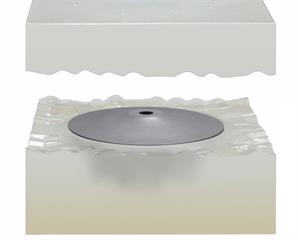

Much the same as waxes, wicks, colors and scents, there are various sorts of flame making molds that you can purchase out there. They are made in a wide range of shapes and estimates and what you purchase is truly up to what your inclination is and how much cash you need to spend on it. A form is essentially what you empty the hot wax into to make the shape. It will chill off and afterward you simply evacuate the form. As should be obvious that there will be an assortment of the size and shape you can look over there will likewise be an assortment of what kind of material the light creation form is produced using. These will run from metal, aluminum and plastic to polyurethane, elastic or latex. Regardless of which one you pick simply ensure that you recall that the base of the form is really the head of the flame. On the off chance that you go with a metal shape you will find that it is tougher and longer enduring then the others.

Aluminum molds are straightaway. These kinds of molds are likewise normally utilized by flame producers since they are more modest than a few and will give an incredible method to hold your light set up. Dealing with any form you purchase is significant. You would prefer not to scratch the form within the flame since it will make your light appear to be unique when the wax cools. In the event that you keep your form cold if will give an increasingly crude appearance while the hotter molds will give more of a sparkle appearance. Metal flame making silicone rubber molding give much less assortment then a portion of the lesser costly ones. Plastic forms for example will give you much more plans to look over so as to make a portion of the more extraordinary candles.

Another course as expressed over that you can go is polyurethane molds. These particular sorts of molds are truly solid and if very much taken consideration can last as long as ten years or more. It is significant that you comprehend that it is more costly but since of the solidness of the material you will counteract the expense of supplanting it later on. Silicone molds are another alternative in the event that you so decide to utilize them. In a manner they are somewhat similar to elastic and latex since they are delicate and adaptable which permits the flame producer to make his own shapes. Something with silicone that you need to keep an eye out for is that they are difficult to keep up.